Company Information

DEYI Machinery Co.,Ltd.professional manufacturer of screw and barrel of key enterprises,the company is committed to:conical twin screw,parallel twin-screw,single-screw extruders,injection molding machines,rubber melt glue machine,fiber machine,Del foam extruder barrel screw------main components of professional production.Materials used 38CrMoALA steel,the quenching and tempering,qualitative, nitrogen,a polishing process,refined,with long life,wear resistance,good corrosion resistance,etc.,it can be used to replace foreign advanced equipment and Equipment domestic high-performance devices.

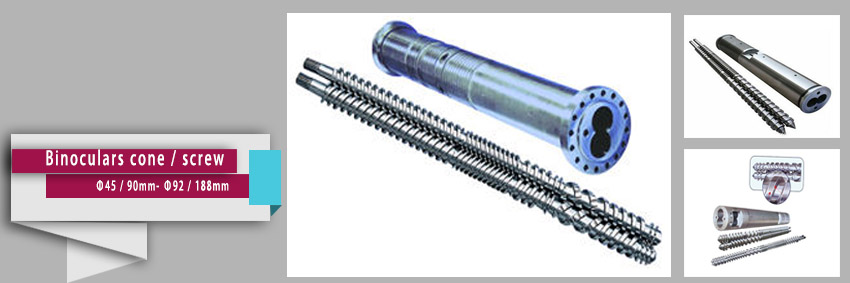

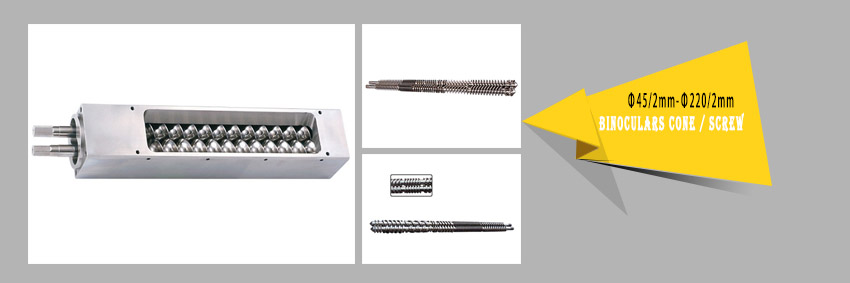

Product Description

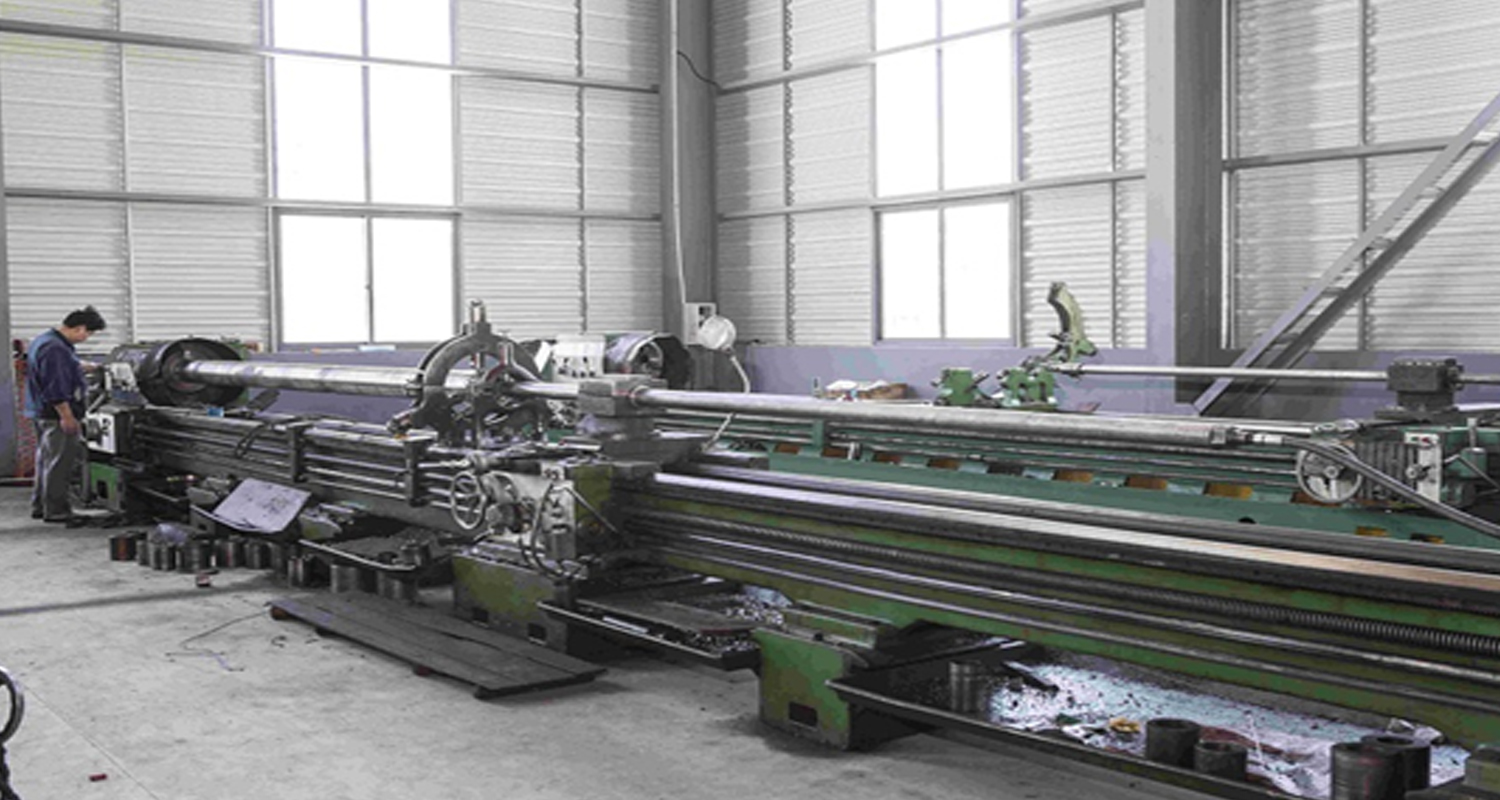

Technology Advantage

38CrMoAIA Screw and Barrel for Plastic Injection Molding

Using machining center finishing, reasonable processing technology, advanced testing equipment, to ensure that the processing accuracy of each product.

Twin-screw extruder screw element:

- convenient interchangeability by agile combination.

- fulfill efficient self-cleaning, transmission, compounding, pressure-forming and etc.

- made of high tool speed W6Mo5Cr4V2, or anti-corrosion steel 38CrMoAlA by speed treatment.

The flexible modular principle is realized with screw barrel sections from the wide range of different designs possible. Fast, intensive and uniform heating of the screw barrel section is ensured by electrical heaters. The barrel sections are cooled with water by means of an internal bore system with bores arranged close to the inside barrel wall.

Products Parameter

38CrMoAIA Screw and Barrel for Plastic Injection Molding

Specifications: Φ20mm- Φ300mm

Aspect ratio: L / D = 15-65

Materials and Technology:

1. 38CrMoALA nitriding treatment

Nitriding depth: 0.5-0.8mm, nitriding hardness: HV≥920

2. 42CrMo Plating: induction hardening + plating / double metal plating PTA +

Chrome hardness: ≥HV800, thickness 0.03-0.05mm, roughness Ra0.2um

3. SKD61 quenching, vacuum quenching overall hardening treatment

Hardness index: HRC> 55-58, straightness 0.015mm / m, roughness Ra0.4um

4. 9Cr18Mov vacuum hardening, CNC circular grinding

Hardness index: HRC> 50-55, straightness 0.015mm / m, roughness Ra0.4um

5. hard chromium plating Specifications:

Chrome plating thickness: 0.05-0.10mm, chrome layer hardness: HV≥960

ess Ra0.4um

Workshop

38CrMoAIA Screw and Barrel for Plastic Injection Molding

Our Services

38CrMoAIA Screw and Barrel for Plastic Injection Molding

1.After sales service: we will dispatch professional technicians to customer factory for machine installation and training.

2. Our Customer Service Executive will be 24 hours online for you to solve problems.

3. We have introduced South Korea and Taiwan technology with more than 30 years experience. Our machine quality is the best.

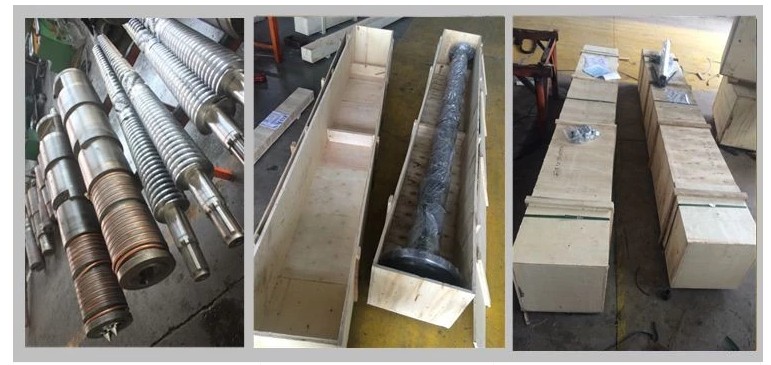

Packaging & Shipping

38CrMoAIA Screw and Barrel for Plastic Injection Molding

FAQ

38CrMoAIA Screw and Barrel for Plastic Injection Molding

Q:. Why I choose your company?

A: a, our company have made screw and barrel parts for many years with strong

experience and advanced technics

b, Best Quality & Best Service with Competitive price.

c, 100% inspection Before Shipment. And we have got CE certificate

d, we have Professional technical team, will supply 24 hours service

f, our machine have good quality, 1 year guarantee and lifetime maintenance

Q:. What about your delivery date and quality?

A: We have good production and inspection facilities and excellent teams of management, technology to

ensure the delivery date and quality of the goods. Lots of stock are available.

Q: What about your warranty?

A: We offer 12 months warranty under normal use,and refresh once replace ones happen.